Discover the last paper of TU/e in collaboration with ENGIE, on “Techno-economic assessment of the one-step CO2 conversion to dimethyl ether in a membrane-assisted process” published in Journal of CO2 utilization”!

Authors: Serena Poto, Thomas Vink, Pierre Oliver, Fausto Gallucci, M. Fernanda Neira d’Angel

Journal of CO2 Utilization, Volume 69, March 2023, 102419

https://doi.org/10.1016/j.jcou.2023.102419

Abstract

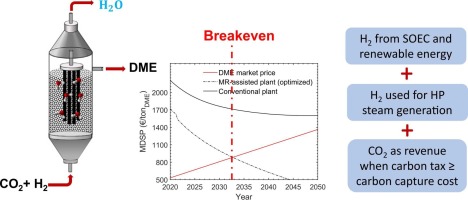

This study investigates the impact of the membrane reactor (MR) technology with in-situ removal of water to boost the performance of the one-step DME synthesis via CO2 hydrogenation at process scale. Given the higher efficiency in converting the feedstock, the membrane reactor allows for a remarkable decrease in the main cost drivers of the process, i.e., the catalyst mass and the H2 feed flow, by ca. 39% and 64%, respectively. Furthermore, the MR-assisted process requires 46% less utilities than the conventional process, especially in terms of cooling water and refrigerant, with a corresponding decrease in environmental impact (i.e., 25% less CO2 emissions). Both the conventional and MR-assisted plants were found effective for the mitigation of the CO2 emissions, avoiding ca. 1.4–1.6 tonCO2/ton DME. However, given the higher reactor and process efficiency, the membrane technology contributes to a significant reduction (i.e., 25%) in the operating costs, which is a remarkable improvement in this OPEX intensive process. Nevertheless, the calculated minimum DME selling price (i.e., 1739 €/ton and 1960 €/ton for the MR-assisted and the conventional process, respectively) is over 3 times greater than the current DME market price. Yet, with the predicted decrease of renewable H2 price and a zero-to-negative cost for the CO2 feedstock, the MR-assisted system could become competitive with the benchmark between 2025 and 2050.